2020 官网升级中!现在您访问官网的浏览器设备分辨率宽度低于1280px请使用高分辨率宽度访问。

Metal 3D Printer

--Reduce Consumption and Increase Efficiency, Create Green ProductivityFocusing on the design and manufacturing of high-precision, large-sized, and multi laser metal 3D printing equipment, AVIMETAL focuses on innovative breakthroughs in LPBF (Laser Powder Bed Fusion) and has independently developed a series of metal 3D printers (such as MT170, MT170H, MT280, MT400M, MT450, MT650, MT800H, etc.). Compared to traditional cutting, LPBF significantly reduces waste and achieves a utilization rate of over 95% for metal powder materials.

The MT series equipment is equipped with self-developed AVI Control (intelligent control software) and AVI Pretreatment (data preprocessing software). The entire printing process is intelligent, controllable, and traceable. It also supports the installation of intelligent powder supply system and AVIMES digital management platform. This significantly increases the energy consumption of continuous production on the production line, helping customers build smart low-carbon factories.

Up to date, more than 100 units have been installed and applied in high-end manufacturing industries such as aerospace, biomedicine, and automotive molds. AVIMETAL is committed to assisting various industries in efficient production, industrial upgrading, and high-quality development.

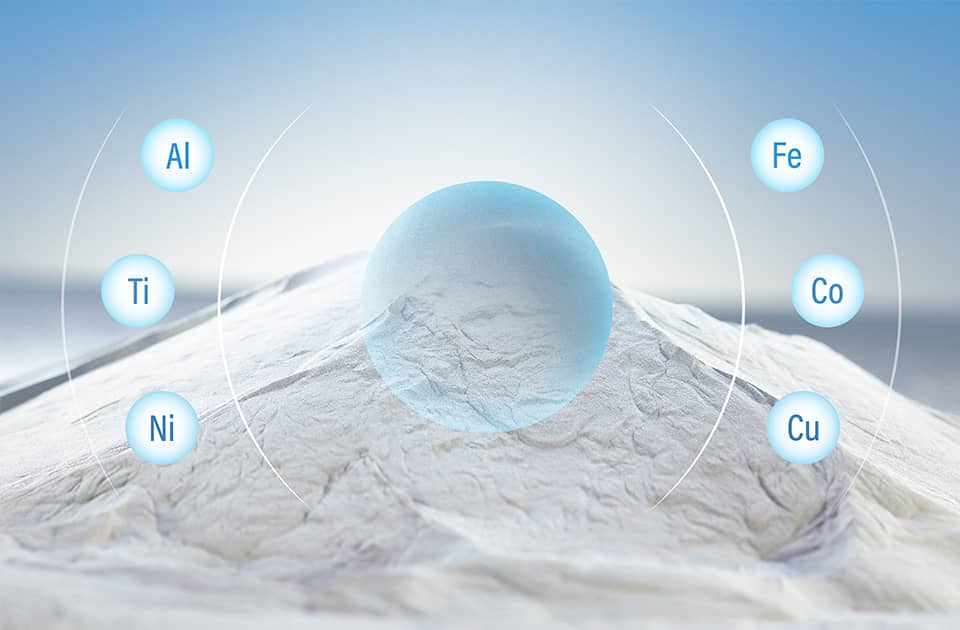

Metal 3D Powder

--Circular Regeneration, Closed-Loop Sustainable DevelopmentAVIMETAL has produced high-performance powders (Titanium Alloy, Superalloy, Aluminum Alloy, Iron-based Alloy, Cobalt-based Alloy, etc.) through five major atomization powder metallurgy technologies (AVI-VIGA/EIGA/PREP/PA/GA). These powders have low oxygen content, high sphericity, and excellent comprehensive formability.

In the field of high-value titanium alloy powder, AVIMETAL has created a closed-loop system of "Production Recycling Regeneration" for titanium powder. By recycling titanium alloy coarse powder or debris (with a waste powder regeneration rate of 100%), the dependence on primary material resources is greatly reduced. At the same time, it also achieves the recycling and utilization of waste resources. This can release approximately 1800 tons of high-quality titanium powder annually for the market.

All-in-One Solution

Green Intelligent Manufacturing Empowers the Low-Carbon TransformationAVIMET is committed to providing one-stop services for equipment, materials, and processes with the corporate mission of "Print the Future, Beauty the World".

In the aerospace industry, AVIMETAL has developed high-precision and large-sized printers such as MT650, MT800H, and MT1550, and innovated in metal materials such as Superalloy, Titanium Alloy, and Aluminum Alloy. This promotes the integration of complex structures and lightweight forming, reducing weight and consumption for industry parts.

In the biomedical industry, AVIMETAL has developed a series of advanced medical metal powder materials, such as Cobalt Alloy, Titanium Alloy, etc., as well as metal 3D printers MT170DL, MT170H, MT280. This has facilitated precise printing of personalized implants, reduced surgical consumables waste, and promoted the development of regenerative medicine.

In the consumer electronics industry, AVIMETAL has developed a metal 3D printer MT400M and high-strength, durable Titanium Alloy. This provides the possibility for the multidimensional goals of near net forming of precision parts, reduction of carbon emissions in the supply chain, and sustainable development of the industry.

In the automotive mold industry, AVIMETAL has improved production efficiency and quality through rapid prototyping design and integrated manufacturing, promoting industry innovation and sustainable development.

Humanistic Value System

Caring for Employees and Supporting Career GrowthFocusing on employee improvement, AVIMETAL conducts a series of job training, provides multi-channel development opportunities, and offers a series of specialized training courses.

We support employees to pursue further education and apply for talent projects, providing every employee with broad development space and growth environment, and forging pioneering talents for the high-quality development of the industry.

AVIMETAL also regularly organizes various themed activities to continuously enhance employees' sense of belonging and satisfaction.

Metal 3D Printing

Promote Inclusive Technology and Shared ValueAVIMETAL supports the development of education and collaborates with multiple universities to research and innovate cutting-edge technologies and products. We have established an off campus activity "training base" to explore the co education model of diverse skilled talents and provide professional talents for the industry.

In terms of industry skill competitions, AVIMETAL has co organized multiple events such as the "47th World Skills Competition Additive Manufacturing Project Beijing Selection Competition" and the "2nd National Skills Competition CAD Mechanical Design (National Selection) Project Beijing Selection Competition". We continuously provide technical support to assist in the training of national vocational skilled talents.

AVIMETAL has always actively promoted the popularization of green and intelligent manufacturing industry standards for metal 3D printing. We have participated in the drafting, argumentation, and revision of over 10 national and industry standards, contributing to the standardized development of the metal 3D printing industry.

Corporate Integrity Concept

Transparent and Compliant Governance, Building a Solid Foundation for DevelopmentAVIMETAL always adheres to transparent governance and honest operation, and regards compliant operation as the lifeline of enterprise development. To ensure that every business decision and process strictly complies with laws, regulations, and industry standards.

Innovation drives development. AVIMETAL continuously increases its R&D investment, with technological innovation as the fundamental driving force for enterprise development. The R&D team has more than 100 people now, accounting for 25% of the total. The company has obtained over 100 industry patents and software copyright authorizations.

AVIMETAL actively focuses on risk management, forward-looking risk prevention and control, and strengthens the construction of supply chain resilience. We have implemented dual source procurement for key raw materials and established a comprehensive risk response plan for supply disruptions.

With technological innovation as the core, AVIMETAL fully practices ESG responsibility from green production, talent cultivation to compliance governance. In the future, we will continue to deepen the innovation loop of "equipment material process", jointly build a sustainable manufacturing ecosystem with global partners, and inject technological momentum into the development of the industry!