SLM printing fixed denture

Adopting the additive manufacturing, the fixed denture is printed by laying powder layer by layer. 246 pieces could be printed in 4.3 hours from a whole plate at a time, with smooth interior of the crown and less sticky powder on the outside, and the comprehensive dimensional accuracy effectively controlled within 0.1mm.

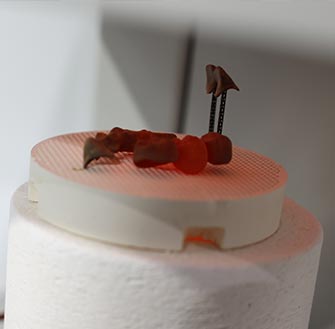

Brackets

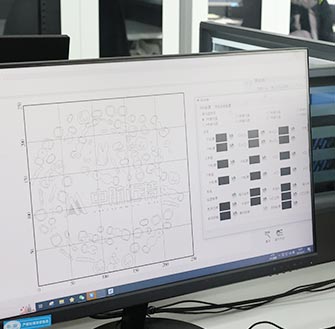

Scheme

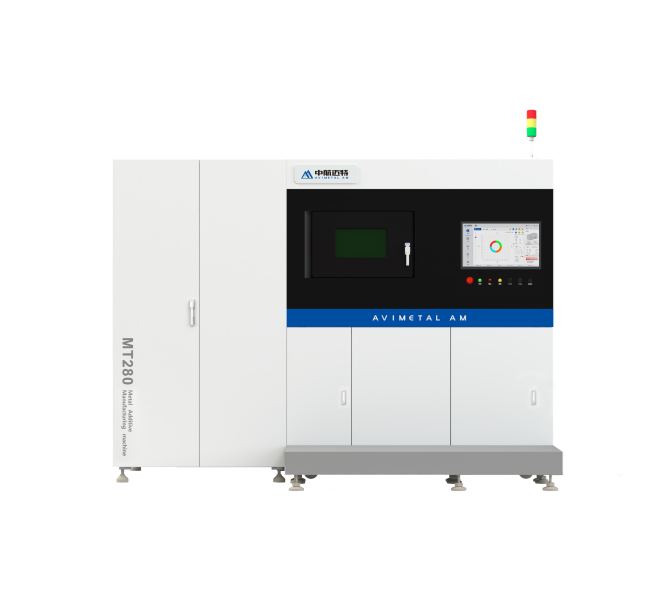

MT160

CoCr01

E-stage support design to ensure the support strength, the convenience to clear powder and support removal and save the use of powder

Result

28 metal brackets of 46mm high could be printed from a whole plate in 7 hours, with smooth surface, no obvious step pattern. The linkage and E-Stage support method ensure a good fitness, maximizes productivity and efficiency, and regulates effectively the comprehensive dimensional accuracy within 0.1mm.

Porous Medical Components

Scheme

MT160

Ti64 G5

Optimization of printing parameters and designs of support methods and placement

Result

Using small spot for printing porous lattice structure to ensure the fine rod diameter molding while adjusting the spot compensation and energy density to control the printing size. Using reasonable placement angle and cross support structure to ensure powder saving, good molding and high productivity.