① The MT400M equipment shines with four lasers, advancing the rapid and precision forming of complex components.

With an build size of 420×350×400mm, it accurately meets industrial manufacturing needs, enabling industrial users to achieve integrated rapid forming of large and medium-sized complex components.

② Multi-size forming equipment meets diverse mass production needs.

Catering to various industrial fields, AVIMETAL’s series of multi-laser metal 3D printers, including models such as the MT170, MT170H, M280, and MT450, cover a range of sizes. The series fully supports open-source printing modes, allowing users to independently adjust process parameters and achieve a high degree of customization in materials, structures, and application scenarios.

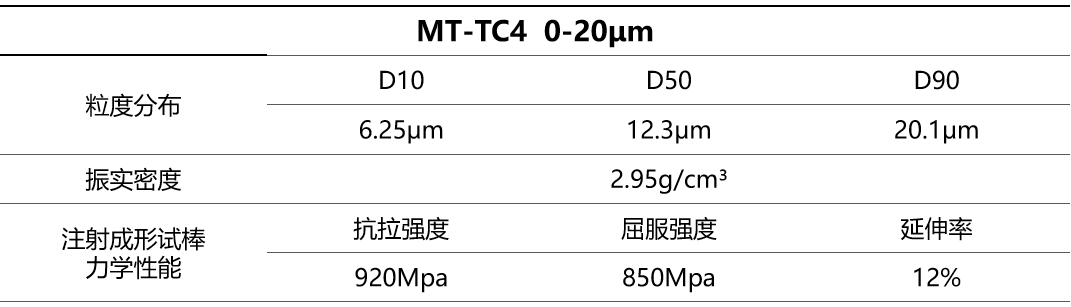

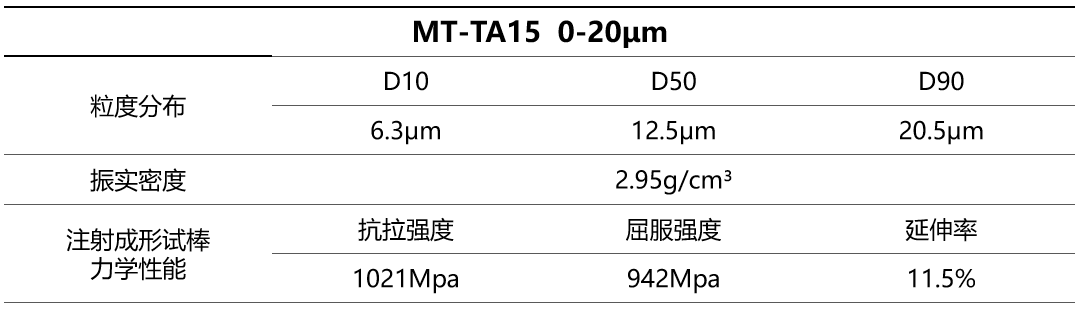

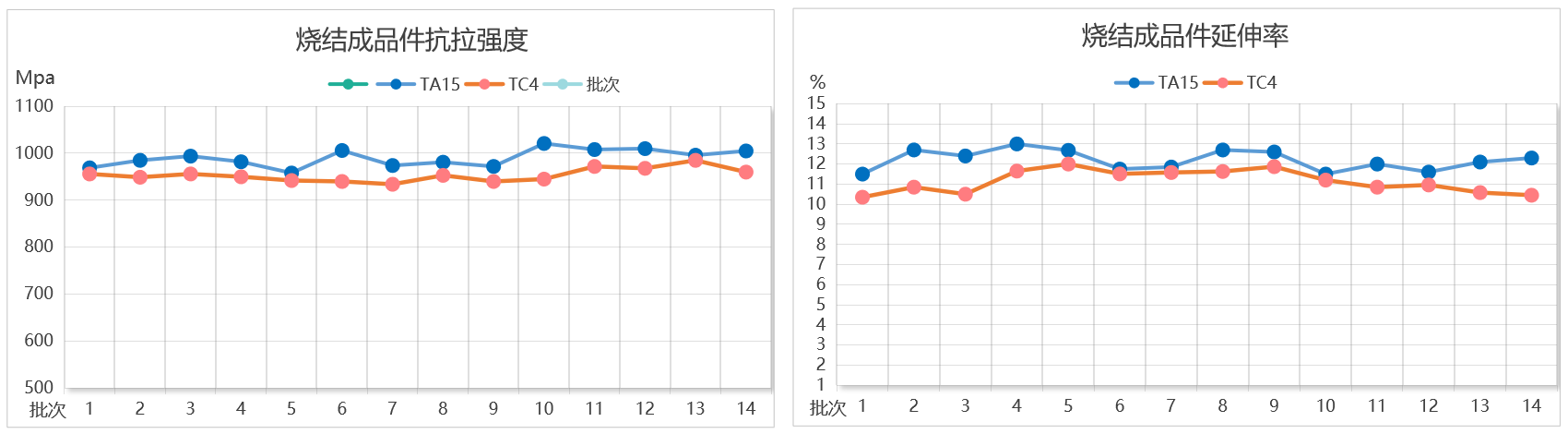

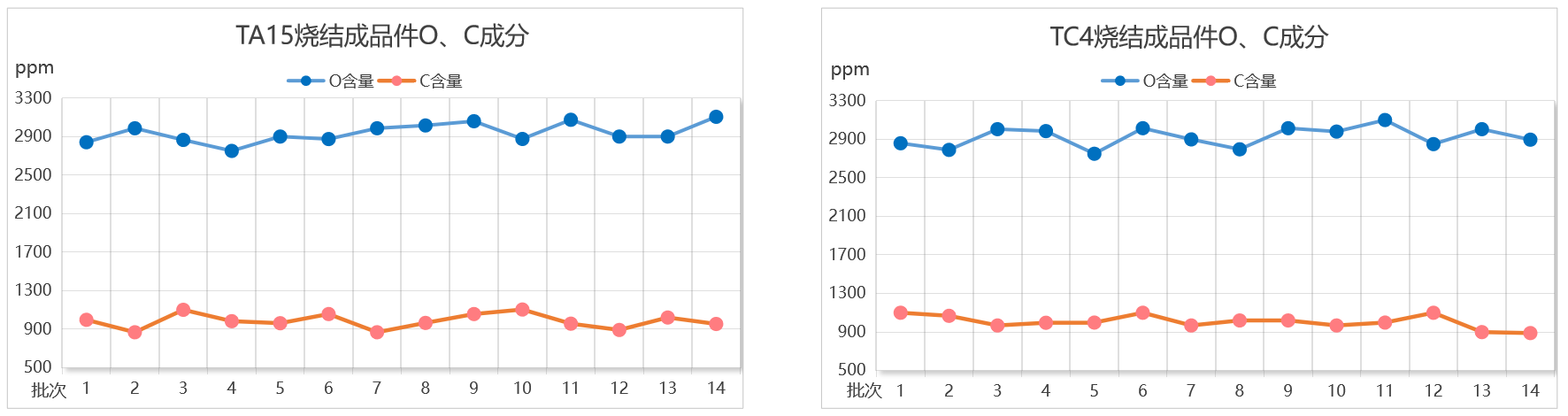

③ MT-TC4/TA15 titanium powder and feedstock redefine MIM lightweight and high-performance.

Leveraging aerospace-grade titanium alloy material technology, AVIMETAL has developed MT-TC4 and MT-TA15 ultra-fine titanium alloy powders and feedstocks. With excellent properties such as lightweight, high strength, corrosion resistance, and biocompatibility, they are particularly suitable for applications in 3C electronic precision components, porous heat dissipation structures, orthopedic implants, dental implants, and high-end equipment structural parts.

④ 100% material recycling process drives sustainable manufacturing upgrades across multiple industries.

At this exhibition, AVIMETAL showcased a series of new powder materials, such as MT-IN939G/K438/CM247LC superalloys, MT-AlMgErZr/AlMnErZr high-strength aluminum alloys, and MT-Ti65/Ti55531 titanium alloys, meeting demands for extreme working conditions and expanding application scenarios in aerospace and high-end equipment.

Focusing on material preparation, AVIMETAL has pioneered breakthroughs in 100% recycled powder production technology, building upon advanced atomization processes such as AVI-VIGA/EIGA/PREP/PA/GA. By recycling returned materials and processing them through regenerative technology, metal powders suitable for 3D printing within the 0-53μm range are produced, with comprehensive performance comparable to that of virgin atomized powders. This not only contributes to the industry’s environmental standards and green supply chain upgrades but also meets downstream customers’ demand for sustainable raw materials. It supports clients in establishing high-end green supply chains and building a closed-loop “production-use-recovery-regeneration” system.

⑤ Integration of equipment and materials innovation breaks through mass production bottlenecks in automotive molds, 3C, and other industries.

At the exhibition, AVIMETAL presented a series of customer application validation cases manufactured using its precision multi-laser metal 3D printing equipment and high-performance materials. These cases offer new pathways for mass manufacturing in fields such as automotive molds, consumer electronics, and aerospace.